What is a Pole Barn?

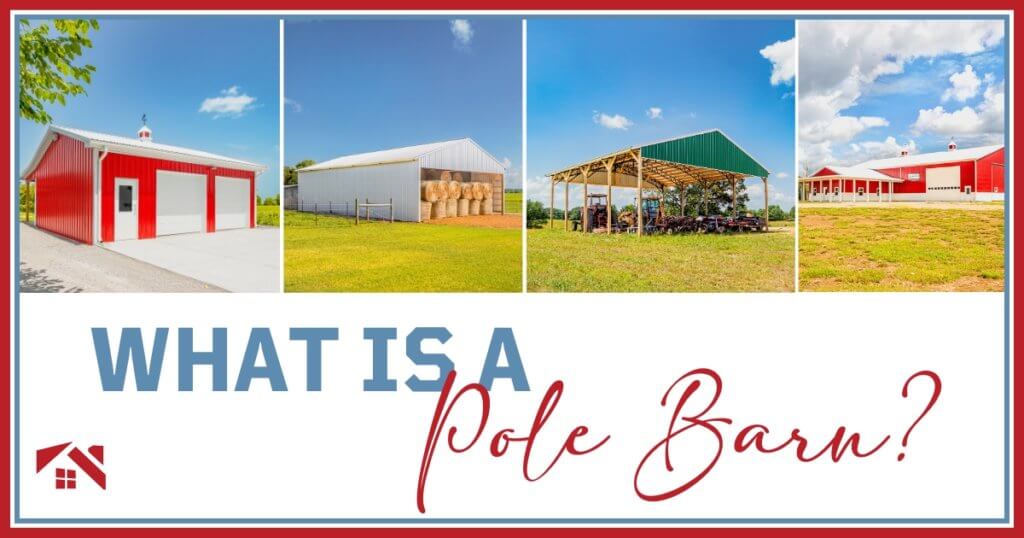

When it comes to getting the most out of your space—without overcomplicating the process—a pole barn just makes sense. But maybe you’re wondering what a pole barn is and if it’s right for you. These buildings are known for their strength, simplicity, and versatility, whether you’re needing a spot for your tools, your tractor, or a weekend project. Around here, we’ve seen folks use them for everything from backyard garages to full-scale farm storage. In the sections ahead, we’ll walk you through what makes a pole barn different, how it’s built, and why it might be the right fit for your next project.

A pole barn—also known as a post-frame building—is a simple yet sturdy structure built using large posts set directly into the ground or on a foundation. Instead of relying on interior load-bearing walls, the strength comes from those posts and the framing that connects them, which allows for wide open interior spaces and flexible layouts. Pole barns are often finished with metal roofing and siding, making them both durable and low-maintenance. Whether you’re building a barn, garage, workshop, or storage building, this construction method keeps things strong, straightforward, and cost-effective.

Pole barns first started popping up in the United States around the 1930s, during the Great Depression, when farmers needed to build quickly and affordably with whatever materials they had on hand. Utility poles—often surplus from telephone and power lines—were an easy solution for framing, which is where the term “pole barn” comes from. Over time, this practical building method evolved into what we now call post-frame construction, using engineered posts, modern materials, and refined techniques. What began as a simple solution has grown into one of the most reliable and efficient ways to build just about anything.

A pole barn—also known as a post-frame building—is a simple yet sturdy structure built using large posts set directly into the ground or on a foundation. Instead of relying on interior load-bearing walls, the strength comes from those posts and the framing that connects them, which allows for wide open interior spaces and flexible layouts. Pole barns are often finished with metal roofing and siding, making them both durable and low-maintenance. Whether you’re building a barn, garage, workshop, or storage building, this construction method keeps things strong, straightforward, and cost-effective.

Pole barns first started popping up in the United States around the 1930s, during the Great Depression, when farmers needed to build quickly and affordably with whatever materials they had on hand. Utility poles—often surplus from telephone and power lines—were an easy solution for framing, which is where the term “pole barn” comes from. Over time, this practical building method evolved into what we now call post-frame construction, using engineered posts, modern materials, and refined techniques. What began as a simple solution has grown into one of the most reliable and efficient ways to build just about anything.

From classic farm buildings like hay barns, livestock shelters, and equipment storage, to modern garages, backyard workshops, and even small business spaces, their versatility is hard to beat. Because pole barns offer wide open interiors without the need for interior support walls, they’re easy to customize for whatever you need: tool storage, RV parking, hobby space, or even a man cave or she-shed. With the right layout and finishes, a pole barn can work hard, look good, and fit right into your everyday life.

You’ll often hear “pole barn” and “post-frame construction” used interchangeably—and they’re closely related. “Pole barn” is the more traditional term, originally referring to those old structures we talked about earlier that were built with utility poles as the main supports. Over time, the method evolved into what we now call post-frame construction, which uses engineered posts, precision framing, and modern materials for greater strength and efficiency. So while the terminology has grown up a bit, the idea is still the same: a practical, reliable way to construct buildings.

When choosing how to build, one of the biggest decisions is the framing method. Pole barns (or post-frame buildings) and traditional stick-built structures each have their place, but they’re designed—and priced—very differently. Stick-built construction uses a continuous foundation and closely spaced studs, while pole barns use widely spaced structural posts and a simpler foundation setup. That means less material, faster build times, and more flexibility with a pole barn—especially when you don’t need a second story or finished interior like a home.

Here’s a side-by-side look at how they compare:

Feature | Pole Barn / Post Frame | Stick Built | Standard Barn (Timber Frame) |

Framing | Posts spaced 8–12 ft apart, anchored in ground | Studs spaced 16–24 in apart, continuous wall framing | Large timbers, often mortise & tenon joints |

Foundation | No full foundation required (can use piers or slab) | Full poured concrete or block foundation required | Typically uses concrete or stone footings |

Construction Time | Faster to build—fewer materials, less labor | Slower—more detailed framing and finishing work | Labor-intensive and time-consuming |

Cost Efficiency | Lower cost—materials and labor savings | Higher cost—more materials and site prep | Highest cost due to specialty materials/labor |

Interior Space | Wide open span—no interior load-bearing walls | Load-bearing walls may limit layout flexibility | Open interior, but with heavy structural beams |

Uses | Garages, barns, workshops, storage, ag buildings | Homes, finished buildings, offices | Classic barns, heritage-style builds |

Insulation Options | Easily insulated with deeper wall cavities | Standard insulation methods—limited wall depth | Can be insulated, but requires custom solutions |

Aesthetic Options | Metal siding/roof standard, many custom finishes | Flexible finishes—brick, wood, vinyl, etc. | Rustic and natural finishes |

DIY-Friendly | Yes—many pre-engineered kits available | No—requires skilled trades and inspections | Rarely-requires specialized knowledge |

Feature | Pole Barn / Post Frame | Stick Built | Standard Barn (Timber Frame) |

Framing | Posts spaced 8–12 ft apart, anchored in ground | Studs spaced 16–24 in apart, continuous wall framing | Large timbers, often mortise & tenon joints |

Foundation | No full foundation required (can use piers or slab) | Full poured concrete or block foundation required | Typically uses concrete or stone footings |

Construction Time | Faster to build—fewer materials, less labor | Slower—more detailed framing and finishing work | Labor-intensive and time-consuming |

Cost Efficiency | Lower cost—materials and labor savings | Higher cost—more materials and site prep | Highest cost due to specialty materials/labor |

Interior Space | Wide open span—no interior load-bearing walls | Load-bearing walls may limit layout flexibility | Open interior, but with heavy structural beams |

Uses | Garages, barns, workshops, storage, ag buildings | Homes, finished buildings, offices | Classic barns, heritage-style builds |

Insulation Options | Easily insulated with deeper wall cavities | Standard insulation methods—limited wall depth | Can be insulated, but requires custom solutions |

Aesthetic Options | Metal siding/roof standard, many custom finishes | Flexible finishes—brick, wood, vinyl, etc. | Rustic and natural finishes |

DIY-Friendly | Yes—many pre-engineered kits available | No—requires skilled trades and inspections | Rarely-requires specialized knowledge |

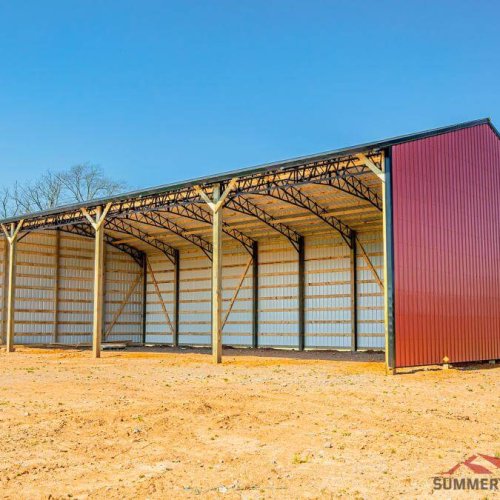

Framing a pole barn looks a little different than traditional construction, but that’s exactly what makes it faster, stronger, and more efficient.

Instead of relying on a full foundation, post-frame construction begins by setting large, treated posts into the ground or on concrete piers. These posts form the structural backbone. From there, horizontal girts are attached between the posts to frame the walls, followed by engineered trusses across the top to create the roofline. Purlins span across the trusses to support the roofing panels.

Once the exterior shell is complete, the interior can be left wide open or finished with walls, insulation, and utilities. The result? A streamlined, high-performance building that delivers strength and flexibility—without the complexity of stick framing.

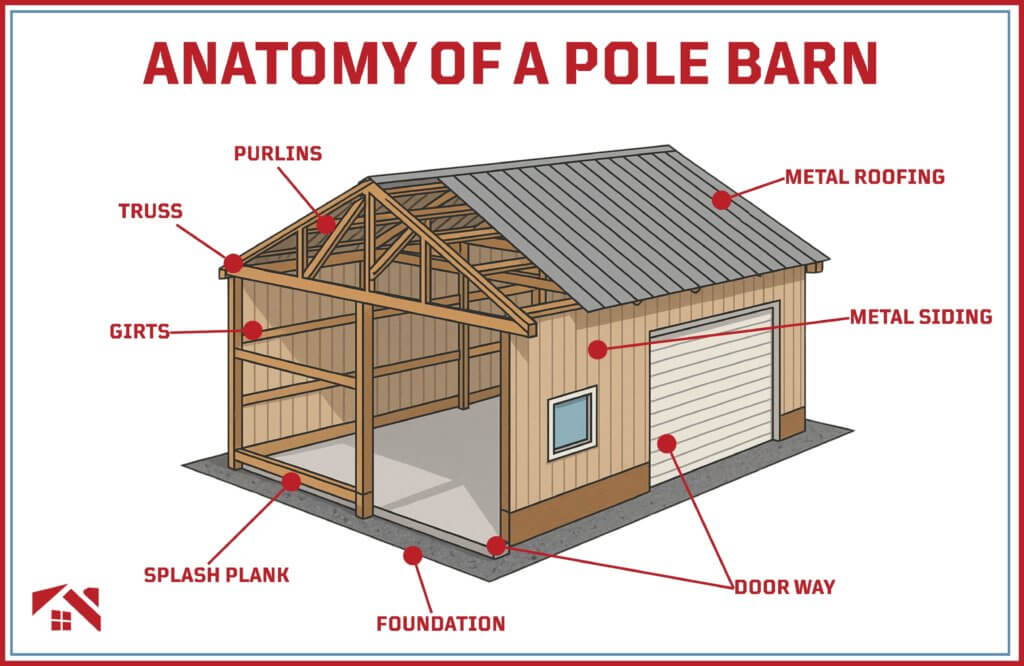

Every pole barn is built around a simple but powerful concept: smart structure that uses fewer materials without sacrificing strength. Here’s a breakdown of the core components that make up a durable, long-lasting post-frame building:

Together, these elements create a strong, flexible structure that’s built to handle heavy winds, snow loads, and years of daily use—without overcomplicating the process.

One of the big advantages of pole barn construction is how flexible it is when it comes to foundations. Unlike stick-built structures that require a full concrete foundation, pole barns can be built on a variety of foundation types—saving time and money without sacrificing strength.

The right foundation comes down to how you’ll use the building, your site conditions, and your budget. No matter the setup, the post-frame design provides a solid, load-bearing structure that stands the test of time.

The right foundation comes down to how you’ll use the building, your site conditions, and your budget. No matter the setup, the post-frame design provides a solid, load-bearing structure that stands the test of time.

The roof on a pole barn does more than keep the weather out—it shapes the look of your building, impacts your interior space, and plays a big role in long-term durability. Thanks to the wide-span strength of post-frame construction, you’ve got options when it comes to your roof design.

Your roof isn’t just a cover—it’s a key part of your building’s strength and character. Whether you’re going for classic utility or something custom, we can help you design a roof that fits your needs and looks great doing it.

Use our 3D building tool to design your own building and get an instant preliminary quote!

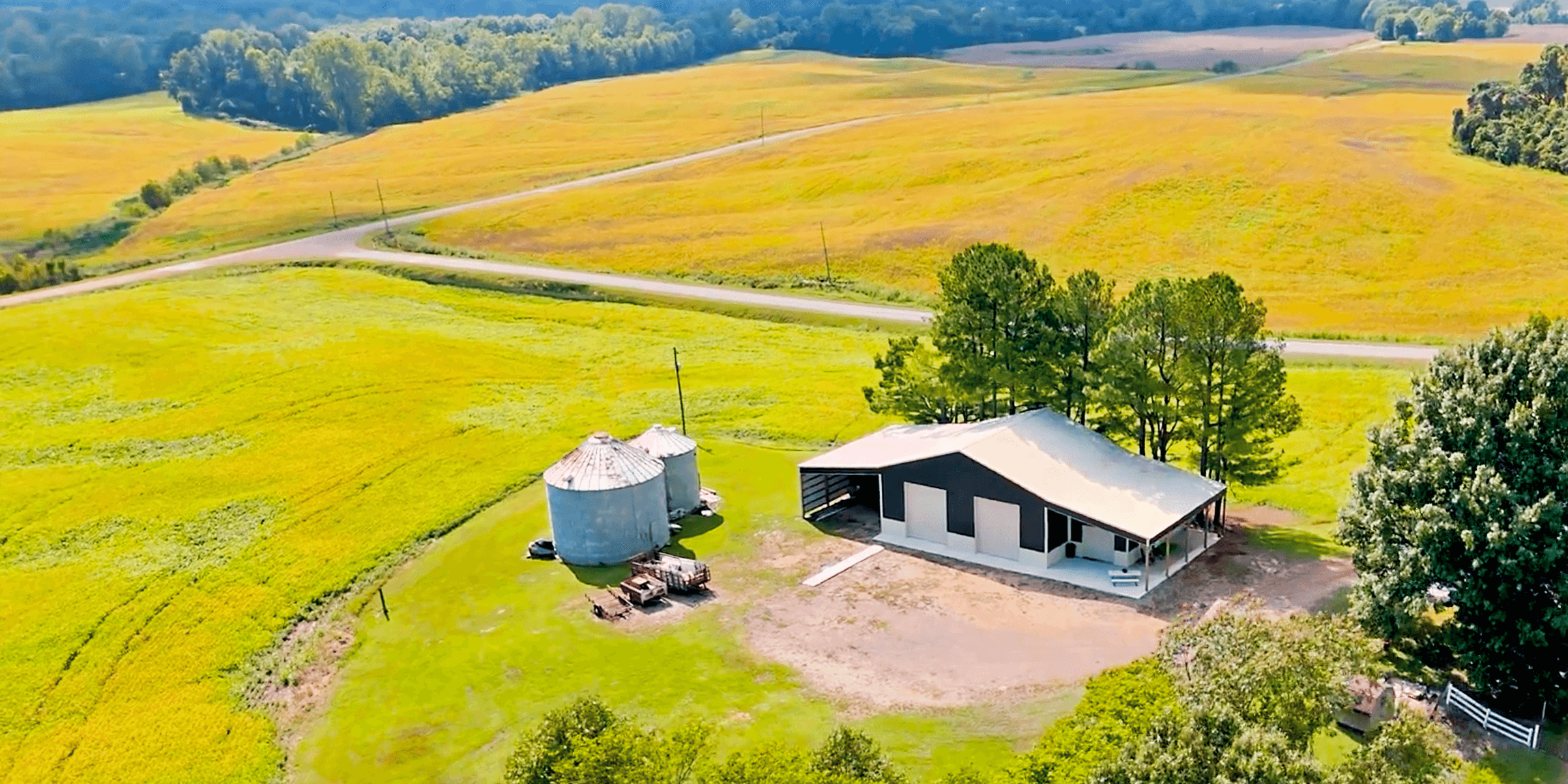

Pole barns are popular for good reason—they’re affordable, fast to build, and flexible enough to fit just about any need. Whether you’re building a barn, garage, workshop, or storage space, post-frame construction gives you strength, space, and customization without the high costs or long timelines of traditional builds. It’s a practical solution that works as hard as you do.

Pole barns use fewer materials and require less labor than traditional construction, which keeps your overall costs down. Without the need for a full foundation or complex framing, you can get more building for your budget.

Because post-frame construction is so efficient, pole barns can go up fast. With pre-engineered materials and a simplified building process, your project can move from foundation to finish in a fraction of the time compared to a stick-built structure.

Whether you need a place to store tractors, park your RV, run a business, or just keep your tools dry, a pole barn can handle it. These buildings can be designed big or small, wide or tall—making them ideal for just about any project you’ve got in mind.

With the structural load transferred directly into the ground through large posts, pole barns are built to stand strong. Add in tough metal siding and roofing, and you’ve got a building that resists rot, pests, and wear—without needing constant upkeep.

Need a wide door for your garage? Want to add a lean-to later on? No problem. Pole barns make it easy to customize layout, openings, and expansions. Plus, they require minimal site prep so you can build where you need to—without jumping through extra hoops.

Designed to handle wind, rain, snow, and sun, a well-built pole barn is made to last through the seasons. With quality materials and proper engineering, your building stays strong and protected, no matter what the forecast throws at it.

Many of our customers take the DIY route—and with the right kit, it’s totally doable. Clear plans, simplified construction, and fewer moving parts mean you can take on the build with confidence, whether you’re a weekend warrior or a seasoned builder.

Our Most Popular Pole Barn Kits

While pole barns offer a lot of benefits, they’re not the right fit for every project. Like any building method, post-frame construction has a few limitations—especially when it comes to more complex designs or residential use. Here are a few things to keep in mind as you plan.

Pole barns shine when it comes to open space and single-story use, but they’re not ideal for multi-story builds or highly detailed architectural finishes. If you’re after a traditional home layout or ornate exterior, a stick-built design may offer more flexibility.

Because most pole barns use metal siding and roofing, it’s important to plan ahead for moisture control. Without the right insulation and vapor barriers, you could run into condensation issues—especially in climates with big temperature swings.

Pole barns can be insulated very effectively, but it takes the right approach. Deeper wall cavities are great for spray foam or insulated panels, but planning matters. You’ll want to think through insulation early if you need year-round comfort inside.

Pole barns don’t require a full foundation, which is great for cost and speed—but it can be limiting in some cases. For example, gravel floors work well for general storage, but if you’re running heavy equipment or finishing the interior, a concrete slab might be a better fit.

If you’re looking to build a pole barn home, financing can be tricky. Some lenders are hesitant to offer mortgages on non-traditional construction or buildings without a full foundation. It’s doable—but you’ll want to check with your lender first.

While a well-built pole barn can add tremendous value, homes built with post-frame construction may be harder to appraise or sell in certain markets. If resale is a key part of your plan, it’s worth talking with a local real estate expert before you build.

Pole barns used for agriculture or storage purposes usually fly through permitting, but if you’re planning to live in one, zoning and code requirements can get more complex. Each county is different, so it’s important to check what’s allowed on your land before you get too far.

At Summertown Metals, we believe in matching the right structure to the right purpose—and while pole barns are an excellent solution for barns, garages, shops, and storage, they’re not the best fit for full-time homes. Post-frame construction isn’t designed for multi-story living, can face insulation and moisture challenges without careful planning, and may bring up hurdles with financing, resale, and local building codes. We want your investment to serve you well long-term, and in most cases, a conventionally framed (stick-built) home is better suited for residential needs. If you love the look and affordability of a pole barn, we’re happy to help you explore barndominium building kits and custom metal home options that bring that same charm with the right structure underneath.

At Summertown Metals, you don’t have to choose between premium materials and a fair price. We source high-quality products with care and pass the savings on to you, giving you the best value in the market without cutting corners. It’s how we make the American Dream more accessible—one build at a time.

We put relationships first, and it shows. From your first phone call to final delivery, you’ll experience a level of care and communication that’s rare in this industry. Our customer service is driven by respect, reliability, and a commitment to putting your needs at the center of everything we do.

You’re not just buying materials; you’re gaining a partner. Our experienced team walks with you through every step, offering honest guidance, clear answers, and design support to help you make informed decisions with confidence. We believe an educated customer is an empowered one.

If you’re looking for a versatile, cost-effective building solution that can adapt to your needs—from storage and workshops to garages and agricultural uses—a pole barn might be just the right fit. At Summertown Metals, we know that choosing the right structure means balancing durability, affordability, and flexibility. While pole barns offer quick construction and great value, they’re best suited for single-story designs and require thoughtful insulation planning to keep your space comfortable year-round. If you want a hassle-free, customizable metal building that gets the job done without breaking the bank, a pole barn is definitely worth considering.

A pole barn is an ideal fit when you need:

A pole barn is a type of metal-framed building that uses large poles or posts set into the ground for structural support, typically used for storage, workshops, or agricultural purposes.

Pole barns are a type of post frame construction; the terms are often used interchangeably, but post frame is a broader category that includes more advanced engineering and design options.

Yes, pole barns can be insulated using various materials like spray foam or insulated panels, but proper planning is important to prevent moisture issues.

With proper maintenance, a pole barn can last 30 years or more, depending on materials and environmental conditions.

Yes, pole barns are durable structures designed to withstand weather and heavy use, especially when built with quality materials and proper construction techniques.

A self-framing metal building uses its metal panels for structural support, needing no internal frame, while a pole barn relies on posts set into the ground to support the structure. Pole barns are better for larger, open layouts; self-framing buildings work well for smaller, simpler projects.

From pole barns to fully custom builds, our post frame solutions are designed to fit your life and your land. Explore ready-to-go kits or work with our team to create something just for you—quality materials, honest pricing, and expert guidance every step of the way....

Thinking about adding a pole barn to your property? Whether you need extra storage, a place for your animals, or a dedicated workshop, a pole barn is one of the most practical and budget-friendly ways to create functional space that ...